The idea of “building a car” was presented to us back in the fall by TSS parents Mike and Kathy Gisby. More specifically, the car discussed is based on a 1933 Ford Roadster, a kit produced by a company called Factory Five. Initial thoughts…”How cool!” and “Wow, what an opportunity for our kids!” Of course, these comments were followed up with…”How?”

We all agreed that the combined efforts of the car experts at Altezza Restorations and the TSS students would result in an awesome experience. Our hope is that this collaborative effort will not only challenge our students, but also enhance their ability to collaborate, communicate, plan, organize, and problem-solve! So, we all gathered at the Gisby’s shop to figure out how to make this happen. Let the adventure begin…

Today was our first visit to Altezza Restorations, the Gisby’s shop in Bridgeport, CT. Upon arrival, all you could hear was, “a-h-h,” “o-o-h,” “cool,” and “I want one of those!” Joey would like this lambourgini…

The Gisby’s, along with Miles and Gus, gave us a tour of the shop. The students enjoyed seeing the cars displayed on the showroom floor, as well as those in different states of “restoration” throughout the shop.

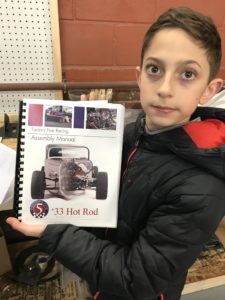

We then gathered at the conference table for a chat about the kit and all the work it will take to craft this masterpiece.

This is where we all agreed on the definition of “HOT ROD” and decided to use it in the name of our car: TSS HOT ROD:

Any car with increased performance or customized in any way to a person or groups preference.

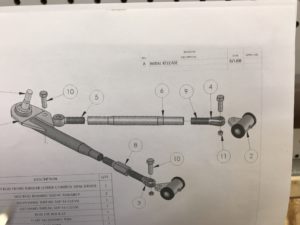

Finally, we got to see the beginning stages of the “TSS Hot Rod,” the space we will be working in, and many of the parts being prepped for its use in the coming weeks:

It became clear by the end of our visit that the final product (TSS Hot Rod) will be greater than the sum of its parts! The pieces of the car, the hands of the experts and students, the minds of all involved, and the passion behind this endeavor will be the driving force behind its success!